Bakery Processing Equipment Market Size, Share, Trends, Growth, and Industry Analysis, By Equipment Type (Ovens, Mixers, Slicers and Dividers, Moulders, Depanners, Proofers, Retarders, Sheeters, Freezers and Coolers, Chillers, Dough Feeding Systems, Pan Greasers and Depositors, Handling Systems, Piston Filling Injectors, and Others), By Mode of Operation (Automatic and Semi-Automatic), By Function (Baking, Kneading, Cooling, Molding, Filling, Mixing, Extrusion, Enrobing, and Others), By Application (Cookies and Biscuits, Breads, Pizza Crusts, Muffins, Cakes and Pastries, Donuts and Croissants, Bagels, Crackers, Pies, Waffles, and Others), By End-Use (Bakery Processing Industry and Food Service Industry), By Distribution Channel (Direct and Indirect), Regional Analysis and Forecast 2032.

Global Bakery Processing Equipment market size was USD 12.16 billion in 2023 and the market is projected to touch USD 19.63 billion by 2032, at a CAGR of 5.47% during the forecast period.

Bakery processing equipment is used in many stages of the bakery production process, such as mixing, forming, baking, cooling, and packaging. The bakery processing equipment market is expanding rapidly as a result of changing consumer preferences, busy lifestyles, and the growing popularity of convenient food options.

Factors driving the market include technological advancements, automation, and the need for increased efficiency and productivity in bakery operations. Manufacturers are constantly innovating to develop equipment that improves product quality, reduces production time, and minimises waste. Additionally, stringent food safety regulations and the need for compliance with hygiene standards further propel the demand for advanced bakery processing equipment.

Geographically, the market is witnessing substantial growth in emerging economies, particularly in Asia Pacific, attributed to rapid urbanization, rising disposable incomes, and changing dietary habits. However, factors such as high initial investment costs and maintenance expenses pose challenges to market growth. Nevertheless, strategic collaborations, mergers, and acquisitions among key players are expected to drive market expansion and foster competitiveness.

Global Bakery Processing Equipment report scope and segmentation.

|

Report Attribute |

Details |

|

Estimated Market Value (2023) |

USD 12.16 billion |

|

Projected Market Value (2032) |

USD 19.63 billion |

|

Base Year |

2023 |

|

Forecast Years |

2024 – 2032 |

|

Scope of the Report |

Historical and Forecast Trends, Industry Drivers and Constraints, Historical and Forecast Market Analysis by Segment- Based on By Equipment Type, By Mode of Operation, By Function, By Application, By End-Users, By Distribution Channel & Region. |

|

Segments Covered |

By Equipment Type, By Mode of Operation, By Function, By Application, By End-Users, By Distribution Channel, & By Region. |

|

Forecast Units |

Value (USD Million or Billion), and Volume (Units) |

|

Quantitative Units |

Revenue in USD million/billion and CAGR from 2024 to 2032. |

|

Regions Covered |

North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. |

|

Countries Covered |

U.S., Canada, Mexico, U.K., Germany, France, Italy, Spain, China, India, Japan, South Korea, Brazil, Argentina, GCC Countries, and South Africa, among others. |

|

Report Coverage |

Market growth drivers, restraints, opportunities, Porter’s five forces analysis, PEST analysis, value chain analysis, regulatory landscape, market attractiveness analysis by segments and region, company market share analysis. |

|

Delivery Format |

Delivered as an attached PDF and Excel through email, according to the purchase option. |

Global Bakery Processing Equipment dynamics

Technological advancements and the use of automation in bakery operations are also key drivers of market growth, as they improve efficiency, consistency, and product quality while lowering labor costs and production times. Furthermore, stringent food safety regulations and hygiene standards require the use of advanced and compliant equipment, driving up market demand.

On the other hand, the market faces challenges such as the high initial investment and maintenance costs associated with modern bakery processing equipment, which can be a barrier to small and medium-sized enterprises. Additionally, the complexity of integrating new technologies into existing production lines and the need for skilled labor to operate sophisticated machinery pose further obstacles.

Despite these challenges, opportunities abound in the form of increasing demand in emerging markets, particularly in the Asia Pacific region, where rapid urbanization and shifting dietary habits are driving bakery product consumption. Strategic collaborations, mergers, and acquisitions among key market players are fostering innovation and competitiveness, leading to a broader range of advanced, efficient, and cost-effective bakery processing solutions.

Global Bakery Processing Equipment drivers

The growing demand for bakery products is a key driver of the Global Bakery Processing Equipment market. Urbanization, rising disposable incomes, and the fast-paced nature of modern life have led consumers to prefer convenient and ready-to-eat food options. Bakery products such as bread, cakes, pastries, and cookies are ideal for this lifestyle, which contributes to their increasing popularity.

Furthermore, the trend toward healthier, artisanal baked goods has increased demand. Consumers are increasingly seeking products made with whole grains, organic ingredients, and fewer preservatives, forcing bakeries to invest in advanced equipment that can produce a diverse range of high-quality products efficiently.

Technological advancements and the integration of automation into bakery processing equipment are driving market growth. Automated mixers, advanced ovens, and high-speed packaging machines improve manufacturing efficiency, consistency, and product quality. These technologies reduce labor costs and production times, allowing bakeries to meet rising demand more effectively. Furthermore, automation reduces human error while ensuring strict adherence to food safety and hygiene standards, which is critical in the food processing industry. Continuously developing smart and interconnected machinery capable of real-time monitoring and data analysis optimizes production processes and improves operational efficiency.

Restraints:

One of the main limitations on the Global Bakery Processing Equipment market is the high initial investment required to purchase advanced machinery. This significant financial investment can be a barrier for small and medium-sized businesses (SMEs) seeking to upgrade their equipment. Additionally, ongoing maintenance and repair costs can increase the financial burden, making it difficult for smaller businesses to remain competitive. These expenses can also discourage new entrants from investing in the most recent technologies, limiting market growth.

Integrating new technologies into existing bakery production lines can be difficult and disruptive, posing yet another significant challenge. The transition to automated and advanced equipment often requires extensive reconfiguration of existing processes, which can result in temporary downtime and decreased productivity. Furthermore, operating sophisticated machinery necessitates a skilled workforce, which can be challenging to find and retain. The need for specialized training and technical expertise increases operational costs and can slow the adoption of new technologies, particularly in regions with limited access to skilled labor.

Opportunities:

The continuous drive for innovation and product diversification creates significant opportunities for the Global Bakery Processing Equipment market. Consumers are increasingly looking for unique, artisanal, and health-conscious bakery products, driving manufacturers to innovate and diversify their offerings. Equipment that can accommodate new ingredients, cater to dietary preferences (e.g., gluten-free or vegan products), and produce novel shapes and flavors is highly desirable. Furthermore, the development of energy-efficient and environmentally friendly equipment is consistent with the growing emphasis on sustainability, creating another avenue for market expansion. Manufacturers can gain a competitive advantage by leveraging technological advancements and responding to changing consumer preferences.

Segment Overview

The Global Bakery Processing Equipment market is divided into various types of equipment required at different stages of bakery production. Ovens are central to baking, with features such as convection, deck, and rotary baking. Mixers are essential when preparing dough or batter, as they ensure the proper consistency and texture. Slicers and dividers make the cutting and portioning process more efficient. Moulders shape dough into desired shapes, whereas depanners help remove baked goods from pans. Proofers and retarders control fermentation, which is essential for dough development.

Sheeters flatten dough to specific thicknesses, and freezers and coolers are essential for keeping products fresh. Chillers keep the appropriate temperature during processing, and dough feeding systems ensure a consistent dough flow. Pan greasers and depositors automate the application of oils and batters. Handling systems, including conveyors, optimize production flow, while piston filling injectors are used for filling pastries. This comprehensive range of equipment ensures a streamlined, efficient, and high-quality bakery production process.

Bakery processing equipment is available in both automatic and semi-automatic modes. Automatic equipment is widely used in large-scale operations due to its ability to significantly increase productivity, consistency, and precision. It reduces the need for manual intervention, thereby lowering human error and labor costs. Semi-automatic equipment, on the other hand, provides a balance of manual control and automation.

It is ideal for smaller operations or artisanal bakeries where a hands-on approach is still preferred. Semi-automatic systems offer flexibility and can be a cost-effective solution for businesses seeking to improve their operations without fully automating. Both modes of operation cater to different scales of production and operational needs, ensuring market versatility.

Bakery processing equipment performs a variety of critical functions during the baking process. Baking equipment, such as ovens, is required for transforming dough into finished products using controlled heat application. Kneading machines ensure that the dough is mixed to the proper consistency, which is important for the product texture. Cooling systems, such as freezers and coolers, keep products fresh after baking.

Molding machines shape dough into specific shapes, whereas filling machines like piston injectors add creams or fillings to pastries. Mixing equipment is essential when preparing dough or batter to ensure uniformity. Extrusion machines help shape dough into continuous shapes such as pasta or snack bars, while enrobing machines coat products with chocolate or other substances. This diversity in function-specific equipment provides comprehensive support throughout the bakery production process.

The application segment of the bakery processing equipment market includes a diverse range of baked goods. Cookies and biscuits require precise shaping and baking, so the equipment is designed to meet those demands. Mixers, proofers, and ovens play critical roles in bread production. Pizza crusts require specialized sheeters and ovens to ensure uniform thickness and baking.

Muffins, cakes, and pastries benefit from mixers, ovens, and filling injectors because of their diverse ingredients and fillings. Donuts and croissants require dough processing equipment such as moulders and fryers. Bagels, crackers, pies, and waffles all have distinct production requirements, which are supported by specialized equipment for mixing, baking, cooling, and finishing. This broad application range demonstrates the versatility and necessity of specialized equipment in the bakery industry.

Bakery processing equipment is used in two main industries: bakery processing and food service. The bakery processing industry includes commercial bakeries and manufacturers who produce large quantities of baked goods for retail or wholesale distribution. These operations require high-capacity, efficient, and dependable equipment in order to maintain productivity and product quality.

The food service industry includes restaurants, cafes, and other businesses that bake and serve baked goods on-site. To meet the diverse needs of their customers, these businesses require equipment that combines performance, versatility, and ease of use. Both segments profit from the technological advancements and automation features of modern bakery processing equipment.

The distribution channel for bakery processing equipment can be either direct or indirect. Direct distribution involves manufacturers selling equipment directly to end users, resulting in a more personalized purchasing experience with the possibility of custom solutions and direct customer support. This channel is useful for developing strong customer relationships and understanding their specific needs.

Indirect distribution, on the other hand, employs intermediaries such as distributors, retailers, and agents to facilitate the sale of equipment. This approach can broaden market reach and provide customers with more options via established sales networks. Both distribution channels play an important role in making bakery processing equipment available to a wide range of customers worldwide.

Global Bakery Processing Equipment Overview by Region

North America and Europe are mature markets with a strong demand for technologically advanced and automated bakery equipment. These regions benefit from well-established bakery industries and strong consumer demand for a diverse range of baked goods. The emphasis in these markets is on efficiency, product innovation, and adherence to strict food safety regulations. The presence of major industry players and continuous investments in research and development further strengthen market growth in these regions.

The Asia Pacific region is witnessing rapid growth in the bakery processing equipment market, driven by increasing urbanization, rising disposable incomes, and changing dietary habits. Countries like China, India, and Indonesia are experiencing a surge in demand for bakery products, both traditional and Western-style, prompting local bakeries and international players to expand their operations. This growth is supported by a burgeoning middle class with a growing appetite for convenient and ready-to-eat foods. Additionally, government initiatives to promote food processing industries and the influx of foreign investments are fostering market expansion in this region. The market here is characterized by the adoption of both basic and advanced bakery equipment to cater to diverse consumer preferences.

Global Bakery Processing Equipment market competitive landscape

Leading companies such as Bühler Group, Ali Group, GEA Group, and JBT Corporation dominate the market due to their diverse product portfolios, technological advancements, and global distribution networks. These companies are constantly investing in R&D to innovate and improve their equipment, with a focus on automation, efficiency, and adherence to strict food safety regulations. Their strong financial positions allow them to pursue strategic mergers and acquisitions, broadening their market reach and consolidating their positions.

Smaller and regional players also make significant contributions to the market by providing specialized and customized solutions to meet specific customer needs. These companies often focus on niche segments or specific types of equipment, providing flexibility and personalized service that larger corporations may not offer. The market is highly competitive, with players competing on various fronts including product innovation, pricing, after-sales service, and customer support. Technological advancements, particularly in automation and smart equipment, are crucial for gaining a competitive edge.

Strategic collaborations and partnerships are common as companies aim to enhance their technological capabilities and expand their market presence. For instance, partnerships with local distributors or service providers help multinational companies penetrate emerging markets more effectively. The growing emphasis on sustainable and energy-efficient equipment is another trend shaping the competitive landscape, with companies developing eco-friendly solutions to attract environmentally conscious customers.

Key Players:

Scope of global Bakery Processing Equipment report

Global Bakery Processing Equipment report segmentation

|

ATTRIBUTE |

DETAILS |

|

By Equipment Type |

|

|

By Mode of Operation |

|

|

By Function |

|

|

By Application |

|

|

By End-Use |

|

|

By Distribution Channel |

|

|

By Geography |

|

|

Customization Scope |

|

|

Pricing |

|

Objectives of the Study

The objectives of the study are summarized in 5 stages. They are as mentioned below:

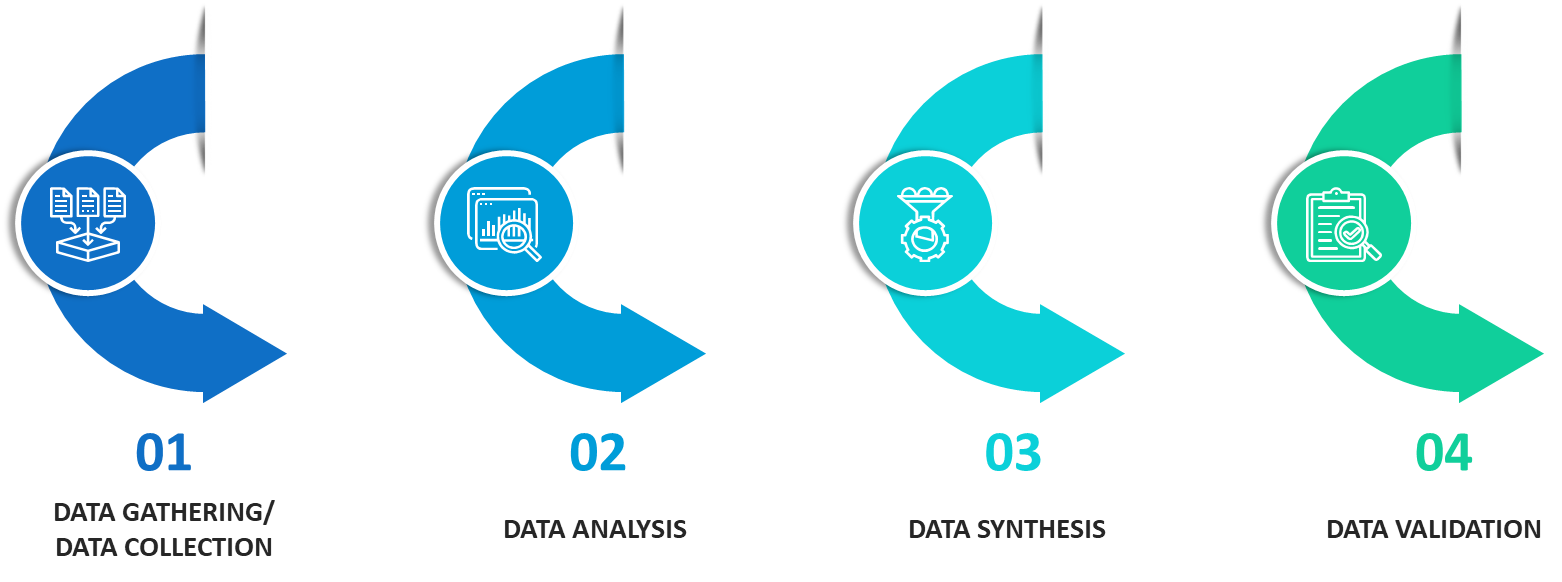

Research Methodology

Our research methodology has always been the key differentiating reason which sets us apart in comparison from the competing organizations in the industry. Our organization believes in consistency along with quality and establishing a new level with every new report we generate; our methods are acclaimed and the data/information inside the report is coveted. Our research methodology involves a combination of primary and secondary research methods. Data procurement is one of the most extensive stages in our research process. Our organization helps in assisting the clients to find the opportunities by examining the market across the globe coupled with providing economic statistics for each and every region. The reports generated and published are based on primary & secondary research. In secondary research, we gather data for global Market through white papers, case studies, blogs, reference customers, news, articles, press releases, white papers, and research studies. We also have our paid data applications which includes hoovers, Bloomberg business week, Avention, and others.

Data Collection

Data collection is the process of gathering, measuring, and analyzing accurate and relevant data from a variety of sources to analyze market and forecast trends. Raw market data is obtained on a broad front. Data is continuously extracted and filtered to ensure only validated and authenticated sources are considered. Data is mined from a varied host of sources including secondary and primary sources.

Primary Research

After the secondary research process, we initiate the primary research phase in which we interact with companies operating within the market space. We interact with related industries to understand the factors that can drive or hamper a market. Exhaustive primary interviews are conducted. Various sources from both the supply and demand sides are interviewed to obtain qualitative and quantitative information for a report which includes suppliers, product providers, domain experts, CEOs, vice presidents, marketing & sales directors, Type & innovation directors, and related key executives from various key companies to ensure a holistic and unbiased picture of the market.

Secondary Research

A secondary research process is conducted to identify and collect information useful for the extensive, technical, market-oriented, and comprehensive study of the market. Secondary sources include published market studies, competitive information, white papers, analyst reports, government agencies, industry and trade associations, media sources, chambers of commerce, newsletters, trade publications, magazines, Bloomberg BusinessWeek, Factiva, D&B, annual reports, company house documents, investor presentations, articles, journals, blogs, and SEC filings of companies, newspapers, and so on. We have assigned weights to these parameters and quantified their market impacts using the weighted average analysis to derive the expected market growth rate.

Top-Down Approach & Bottom-Up Approach

In the top – down approach, the Global Batteries for Solar Energy Storage Market was further divided into various segments on the basis of the percentage share of each segment. This approach helped in arriving at the market size of each segment globally. The segments market size was further broken down in the regional market size of each segment and sub-segments. The sub-segments were further broken down to country level market. The market size arrived using this approach was then crosschecked with the market size arrived by using bottom-up approach.

In the bottom-up approach, we arrived at the country market size by identifying the revenues and market shares of the key market players. The country market sizes then were added up to arrive at regional market size of the decorated apparel, which eventually added up to arrive at global market size.

This is one of the most reliable methods as the information is directly obtained from the key players in the market and is based on the primary interviews from the key opinion leaders associated with the firms considered in the research. Furthermore, the data obtained from the company sources and the primary respondents was validated through secondary sources including government publications and Bloomberg.

Market Analysis & size Estimation

Post the data mining stage, we gather our findings and analyze them, filtering out relevant insights. These are evaluated across research teams and industry experts. All this data is collected and evaluated by our analysts. The key players in the industry or markets are identified through extensive primary and secondary research. All percentage share splits, and breakdowns have been determined using secondary sources and verified through primary sources. The market size, in terms of value and volume, is determined through primary and secondary research processes, and forecasting models including the time series model, econometric model, judgmental forecasting model, the Delphi method, among Flywheel Energy Storage. Gathered information for market analysis, competitive landscape, growth trends, product development, and pricing trends is fed into the model and analyzed simultaneously.

Quality Checking & Final Review

The analysis done by the research team is further reviewed to check for the accuracy of the data provided to ensure the clients’ requirements. This approach provides essential checks and balances which facilitate the production of quality data. This Type of revision was done in two phases for the authenticity of the data and negligible errors in the report. After quality checking, the report is reviewed to look after the presentation, Type and to recheck if all the requirements of the clients were addressed.