Commercial Aircraft Landing Gear Market Research Report: By Gear Position (Main Landing Gear, Nose Landing Gear), By Component (Landing Gear Steering System, Wheel & Brake System, Actuation System, Others), By Aircraft Type (Narrow-Body, Wide-Body, Regional Jet, Others), By Arrangement (Tricycle, Tandem, Tailwheel), and Region (North America, Europe, Asia-Pacific, and Rest of the World) Global Industry Analysis, Size, Share, Growth, Trends, Regional Analysis, Competitor Analysis and Forecast 2024-2032.

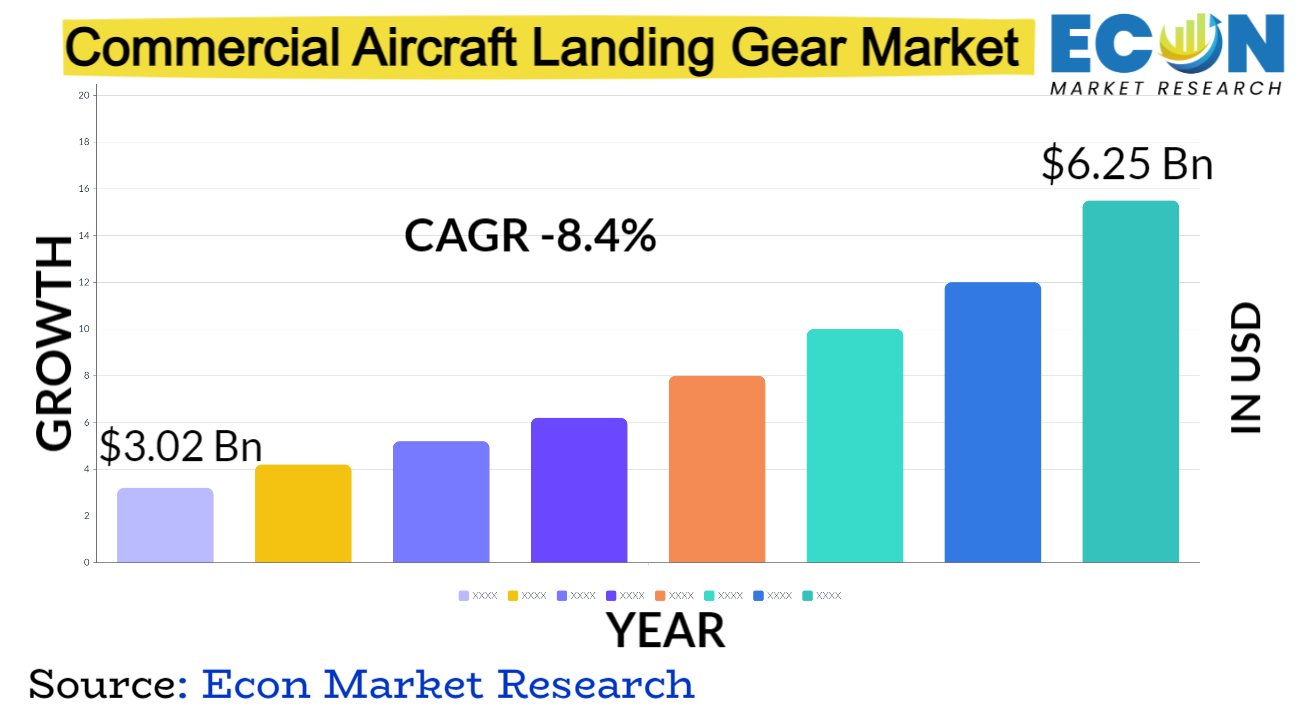

The Commercial Aircraft Landing Gear Market was valued at USD 3.02 billion in 2023 and is estimated to reach approximately USD 6.25 billion by 2032, at a CAGR of 8.4% from 2024 to 2032.

The market for landing gear for commercial aircraft, an essential part of aviation, has changed significantly since its founding. The aviation industry has come a long way since the early 1900s, when airplanes were only equipped with simple fixed landing gear. By improving aerodynamics and safety, retractable landing gear, which was first introduced in the 1930s, drastically changed air travel.

Subsequent decades saw a revolution in landing gear systems due to advancements in materials, design, and technology, which allowed aircraft to handle a wider range of terrain and larger weights. An explosion in demand for durable, lightweight landing gear to accommodate bigger, fuel-efficient aircraft occurred at the start of the twenty-first century, which was a tu ing point for the industry.

Aerospace producers have stepped up their attention on cutting-edge materials that combine lightweight and enhanced durability, such as carbon composites and titanium alloys. Furthermore, enhanced sensor technologies and the integration of electronic systems for predictive maintenance supported safety regulations and operational effectiveness. The market',s trajectory has been shaped by a combined focus on meeting strict safety rules and improving performance. The market for landing gear for commercial aircraft continues to be essential to providing millions of passengers with safe and effective air travel due to ongoing developments in materials, design, and technology.

COMMERCIAL AIRCRAFT LANDING GEAR MARKET: REPORT SCOPE &, SEGMENTATION

| Report Attribute | Details |

| Estimated Market Value (2023) | 3.02 Bn |

| Projected Market Value (2032) | 6.25 Bn |

| Base Year | 2023 |

| Forecast Years | 2024 - 2032 |

| Scope of the Report | Historical and Forecast Trends, Industry Drivers and Constraints, Historical and Forecast Market Analysis by Segment- By Gear Position, By Component, By Aircraft Type, By Arrangement, &, Region |

| Segments Covered | By Gear Position, By Component, By Aircraft Type, By Arrangement, &, Region |

| Forecast Units | Value (USD Billion or Million), and Volume (Units) |

| Quantitative Units | Revenue in USD million/billion and CAGR from 2024 to 2032 |

| Regions Covered | North America, Europe, Asia Pacific, Latin America, and Middle East &, Africa, and the Rest of World |

| Countries Covered | U.S., Canada, Mexico, U.K., Germany, France, Italy, Spain, China, India, Japan, South Korea, Brazil, Argentina, GCC Countries, and South Africa, among others |

| Report Coverage | Market growth drivers, restraints, opportunities, Porter&rsquo,s five forces analysis, PEST analysis, value chain analysis, regulatory landscape, market attractiveness analysis by segments and region, company market share analysis, and COVID-19 impact analysis. |

| Delivery Format | Delivered as an attached PDF and Excel through email, according to the purchase option. |

Commercial Aircraft Landing Gear Market Dynamics

This industry is continuously shaped by changing consumer tastes and an increase in the demand for air travel worldwide. The market is driven by developments in materials science and manufacturing techniques, with a move toward strong yet lightweight materials like titanium alloys and composite materials. Landing gear producers are under pressure to create systems that accommodate larger aircraft while increasing fuel economy and lessening environmental impact.

Strict safety and performance requirements are mandated by regulatory standards, which are crucial. Market trends are impacted by the design, manufacturing, and certification processes when these regulations are followed. Furthermore, the market is susceptible to changes in the airline industry',s dynamics, geopolitical events, and the state of the economy. The need for new landing gear systems or retrofits is greatly impacted by airlines', efforts to mode ize or expand their fleets, which are in tu influenced by factors like passenger demand and fuel prices.

The competitiveness of the market frequently rests on price, functionality, and dependability. Businesses consistently allocate resources towards research and development in order to present inventive solutions that boost productivity, lower maintenance expenses, and increase security. In order to satisfy the changing needs of the aviation sector, partnerships, mergers, and acquisitions also influence market dynamics by promoting technical integration and teamwork. All things considered, the market for landing gear for commercial aircraft is still growing and changing due to developments in technology, industry trends, and regulatory compliance.

Commercial Aircraft Landing Gear Market Drivers

- Technological Advancements

Landing gear systems have become lighter, more robust, and extremely efficient thanks to advances in materials science, manufacturing techniques, and design methodology. Mode materials including high-strength steels, titanium alloys, and carbon composites have greatly lowered weight while strengthening structural integrity, allowing landing gear to endure enormous stresses during landings and takeoffs. Furthermore, production has been expedited by advanced manufacturing processes such as additive manufacturing (3D printing), which have made it possible to produce intricate, lightweight designs that were previously unfeasible using conventional means.

Predictive maintenance capabilities are now available thanks to advanced sensors and embedded technology, which improve safety and save operational downtime by proactively recognizing possible problems. The functionality of landing gear has been enhanced by advancements in control systems and actuators, resulting in more precise deployment, seamless operations, and greater flexibility to accommodate a range of landing scenarios. Furthermore, more intelligent landing gear has been made possible by developments in electronic systems and network connectivity with aircraft, which has facilitated data interchange and increased overall aircraft efficiency.

- Aircraft Mode ization and Expansion

Airlines are always looking for new aircraft models to add to their fleets so they can maximize operational efficiency and handle increasing passenger volumes. The trend toward larger aircraft demands landing gear systems that are able to sustain higher capacity, enhance performance, and guarantee safety. Landing gear has been developed to complement mode aircraft designs, which favor fuel efficiency and operational cost savings.

In response, producers design landing gear systems that can support greater loads without endangering user safety or needlessly increasing weight. This evolution also includes the requirement for landing gear that is versatile enough to work in a variety of airports and locations, regardless of the terrain or operational conditions. , Airlines', expansion plans present opportunities for landing gear producers, particularly in emerging economies where air traffic is expanding rapidly. An essential component of these expansion initiatives is equipping newly ordered aircraft with systems or updating current fleets with more efficient landing gear.

Restraints:

- High Initial Investment and Maintenance Costs

Landing gear system design, development, and certification are complex procedures that need large upfront investments in engineering, research, and specialized manufacturing techniques. When incorporating cutting-edge technologies and sophisticated materials to satisfy the strict performance and safety requirements set by aviation authorities, these expenses increase even more. To further compound the initial price burden, the intricacy of these systems demands extensive testing and validation. Airlines and operators are also severely impacted by maintenance expenses.

Operating costs are significantly increased by the strict maintenance schedules needed for landing gear, as well as the requirement for highly qualified experts and specialized equipment. These financial difficulties are exacerbated by the expense of replacement parts and regular maintenance, which affects the total cost of ownership for these vital elements. Smaller airlines or those with tighter budgets frequently find it difficult to afford these high expenditures, which limits their capacity to invest in more mode , more effective landing gear technologies. Additionally, it may discourage necessary maintenance or replacements, which could compromise the fleet',s overall effectiveness and safety.

- Dependency on Aerospace Industry Cycles

Global events, geopolitical unpredictability, and economic trends all have an impact on the aerospace market',s fluctuations, which in tu affect demand for new aircraft acquisitions and fleet growth. Airlines sometimes postpone or cancel orders for new aircraft during market downtu s or economic downtu s, which lowers demand for the landing gear systems that go along with it. Prolonged economic uncertainty or geopolitical unrest can also cause disruptions to air travel patte s, which in tu lowers demand for passenger flights and cargo shipments.

In response, airlines reduce their fleet sizes, postpone retiring their aircraft, or take other cost-cutting measures, which lessens the immediate requirement for installing or replacing new landing gear. Landing gear suppliers and manufacturers experience periods of lower market demand as a result of these cyclical oscillations, which impacts their revenue streams. Because of the industry',s reliance on periodic cycles, market volatility makes it difficult for businesses to predict demand with any degree of accuracy. Within the landing gear industry, choices about investments, research projects, and production scheduling are also impacted by this dependency.

Opportunities:

- Demand for Next-Generation Aircraft

There has been a disce ible shift toward more sophisticated, fuel-efficient aircraft models as airlines look to update their fleets and satisfy changing passenger demands. The shift to next-generation aircraft, which are distinguished by better aerodynamics, lower emissions, and increased operating efficiency, offers makers of landing gears a great chance to innovate. Landing gear systems for next-generation aircraft must keep up with these developments. Sophisticated landing gear that can accept new aircraft designs, support higher capacity, and guarantee optimal performance can be developed and supplied by manufacturers.

By incorporating cutting-edge materials, like high-strength metals or composite structures, it is possible to create landing gear that is both sturdy and lightweight, which helps mode aircraft achieve their overall weight reduction and fuel efficiency goals. Furthermore, the transition towards environmentally sustainable aircraft solutions presents opportunities for landing gear technology to assume a central role. The sustainability objectives of airlines and regulatory agencies are satisfied by innovations in landing gear systems that minimize environmental effect through improved durability, optimal fuel use, and reduced maintenance requirements.

- Digital Transformation and Automation

There are several benefits to integrating digital technologies into landing gear systems, from increased operational efficiency to better safety protocols. Real-time monitoring and predictive maintenance capabilities within landing gear components are made possible by automation, which is powered by AI, machine lea ing, and sophisticated sensor technologies. The adoption of predictive analytics reduces operating costs for airlines by optimizing maintenance schedules, minimizing downtime, and anticipating possible breakdowns. Furthermore, data collecting and analysis are made possible by the integration of smart sensors and Inte et of Things (IoT) devices into landing gear systems, which promotes proactive decision-making and performance optimization.

By offering a multitude of data about landing gear stress spots, usage trends, and general health, these technologies enable better lifecycle management and maintenance procedures. Digital transformation also makes remote monitoring and diagnostics possible, which facilitates improved communication between maintenance personnel, ground control, and aircraft as well as quick answers to possible problems. This improves operational efficiency overall while simultaneously strengthening safety protocols.

Segment Overview

- By Gear Position

Based on gear position, the global commercial aircraft landing gear market is divided into main landing gear, nose landing gear. The main landing gear category dominates the market with the largest revenue share in 2023.The main landing gear is located beneath the wings or fuselage and supports the majority of the aircraft',s weight during landing and ground operations. These are the larger landing gear assemblies and are usually positioned closer to the aircraft',s center of gravity.

Main landing gear assemblies include wheels, shock absorbers, struts, brakes, and retraction mechanisms. They bear the brunt of the impact during landing and are designed to withstand substantial loads and stresses. ,The nose landing gear is positioned beneath the aircraft',s forward section, supporting a smaller portion of the aircraft',s weight compared to the main landing gear. It primarily aids in steering the aircraft during taxiing on the ground and provides stability during takeoff and landing. The nose landing gear typically comprises a single or dual wheel assembly, shock absorbers, steering mechanisms, and retraction systems.

- By Component

Based on the component, the global commercial aircraft landing gear market is categorized into landing gear steering system, wheel &, brake system, actuation system, others. The landing gear steering system wheel &, brake system category leads the global commercial aircraft landing gear market with the largest revenue share in 2023. The landing gear steering system enables directional control of the aircraft while it',s on the ground. In most commercial aircraft, this system is primarily associated with the nose landing gear. It includes mechanisms for steering the aircraft during taxiing, towing, and ground maneuvers.

Typically, it involves hydraulics, actuators, and steering controls that allow pilots to maneuver the aircraft during ground operations. The wheel and brake system comprises the wheels, tires, brakes, and associated components in both the main and nose landing gear assemblies. These components facilitate the safe touchdown, roll, and stopping of the aircraft during landing. The system incorporates anti-skid technology, hydraulic brake systems, brake control units, and temperature monitoring systems to ensure efficient braking and safe deceleration. The actuation system within the landing gear includes mechanisms responsible for deploying and retracting the landing gear before takeoff and after landing. It involves hydraulic, pneumatic, or electric actuators, gears, and locking mechanisms to ensure the smooth and reliable extension and retraction of the landing gear.

- By Aircraft Type

Based on aircraft type, the global commercial aircraft landing gear market is segmented into narrow-body, wide-body, regional jet, others. The narrow-body segment dominates the commercial aircraft landing gear market. Narrow-body aircraft typically have a single aisle and are designed for shorter to medium-haul flights. Examples include popular models like the Boeing 737 and Airbus A320 families. Landing gear systems for narrow-body aircraft are tailored to handle the weight and operational requirements of these smaller to medium-sized planes, emphasizing efficiency and versatility for shorter routes and higher-frequency flights.

Wide-body aircraft feature a larger fuselage with multiple aisles and are designed for long-haul flights, carrying more passengers and cargo over extended distances. Aircraft such as the Boeing 777, Airbus A330, and A350 fall into this category. The landing gear systems for wide-body planes are engineered to support the increased weight and size of these larger aircraft, focusing on stability, strength, and performance for extended-range operations. Regional jets are smaller aircraft designed for short-haul flights, often serving routes between smaller airports and hubs or connecting regional destinations. These planes, like the Embraer E-Jets or Bombardier CRJ series, require landing gear systems optimized for their specific size, weight, and operational characteristics, focusing on efficiency for regional travel.

- By Arrangement

Based on arrangement, the global commercial aircraft landing gear market is divided into tricycle, tandem, tailwheel. The tricycle category dominates the market with the largest revenue share in 2023. Tricycle landing gear is one of the most common configurations in commercial aviation. It consists of three landing gear assemblies: two main gear units positioned towards the front or middle section of the aircraft',s fuselage and a single nose gear located at the front. This configuration offers enhanced stability during takeoff, landing, and taxiing, particularly in larger commercial aircraft. The nose gear allows for better steering control and facilitates straightforward ground handling.

Tandem landing gear configurations involve the placement of main landing gear assemblies in a tandem or side-by-side arrangement, often beneath the wings or fuselage. This configuration is less common in commercial airliners and is typically found in certain military aircraft or specialized applications. The tandem configuration offers unique weight distribution and structural advantages for specific aircraft designs.

Tailwheel landing gear, also known as conventional landing gear, comprises two main gear units positioned towards the front of the aircraft and a smaller wheel located at the tail or rear section. This configuration was common in earlier aircraft designs and is still utilized in some smaller or vintage aircraft, particularly propeller-driven planes. Tailwheel configurations offer specific handling characteristics, often requiring more skillful piloting during ground operations due to reduced forward visibility and increased susceptibility to ground loops.

Commercial Aircraft Landing Gear Market Overview by Region

The global commercial aircraft landing gear market is categorized into North America, Europe, Asia-Pacific, and the Rest of the World. North America emerged as the leading region, capturing the largest market share in 2023.Numerous well-known aerospace suppliers and manufacturers with a focus on landing gear systems are located in North America. Significant operations are carried out in the area by businesses like Collins Aerospace, Boeing, and others, which support innovative manufacturing techniques, technological advancements, and the creation of landing gear solutions.

The market for landing gear systems is driven by large aircraft manufacturers with significant operations in North America, such as Boeing and Airbus. Because these businesses often design and build aircraft in the area, there is a considerable need for landing gear systems and components. The area gains from a thriving aerospace industry that includes highly qualified labor, large-scale facilities for research and development, and a welcoming regulatory framework. This ecosystem promotes creativity, teamwork, and the manufacturing of superior landing gear systems that adhere to strict performance and safety requirements.

North American airlines are always looking to update their fleets with newer, more fuel-efficient planes. The need for sophisticated landing gear systems that can accommodate the newest aircraft models is created by this push toward fleet renewal, which presents a sizable opportunity for regional producers. Aviation safety and the incorporation of cutting-edge technologies into aircraft systems are priorities in the region. Landing gear systems that have integrated technological solutions and improved safety features are more prominent in the market because they support these aims.

Commercial Aircraft Landing Gear Market Competitive Landscape

In the global commercial aircraft landing gear market, a few major players exert significant market dominance and have established a strong regional presence. These leading companies remain committed to continuous research and development endeavors and actively engage in strategic growth initiatives, including product development, launches, joint ventures, and partnerships. By pursuing these strategies, these companies aim to strengthen their market position, expand their customer base, and capture a substantial share of the market.

Some of the prominent players in the global commercial aircraft landing gear market include AAR, Advantage Aviation Technologies, CIRCOR AEROSPACE PRODUCTS GROUP, Eaton, Hé,roux-Devtek, Honeywell Inte ational Inc., Magellan Aerospace Corporation, Liebherr, MAG Inc., Sumitomo Precision Products Co., Ltd. (SPP), Safran Landing Systems, UTC Aerospace Systems (United Technologies Corporation (UTC)), Triumph Group, Whippany Actuation Systems, and various other key players.

Commercial Aircraft Landing Gear Market Recent Developments

- In March 2023, Recently, Emirates, the well-known airline headquartered in Dubai and the world',s top operator of Airbus A380 long-range aircraft, signed two major contracts with Lufthansa Technik AG for all-inclusive maintenance, repair, and overhaul (MRO) services. According to the agreements, Emirates will receive highly configurable spare parts from Lufthansa Technik for A380 base maintenance operations, such as C-checks and overhauls for the airline',s double-deck flagship aircraft',s main landing gears.

- In January 2023, UAVOS Inc. successfully tested its primary landing gear leaf spring, marking significant advancements in its Medium Altitude Long Endurance (MALE) unmanned aircraft program. Utilizing aircraft prepreg carbon material and high-temperature molding processes, this state-of-the-art leaf-spring system achieves a remarkable 50% strength gain over traditional steel while keeping a lighter and smaller profile.

Commercial Aircraft Landing Gear Market Report Segmentation

| ATTRIBUTE | , , , , ,DETAILS |

| By Gear Position |

|

| By Component |

|

| By Aircraft Type |

|

| By Arrangement |

|

| By Geography |

|

| Customization Scope |

|

| Pricing |

|

No FAQs available.

Report Details

- Published Date:Dec 19, 2023

- Format:PDF

- Language:English

- Delivery:Instant

Download Sample

Get a free sample report to preview the content and quality.