Industrial Automation Market Size, Share, Trends, Growth, and Industry Analysis, By Components (Sensors, Industrial Robots, Industrial PC, Machine Vision, Industrial 3D Printing, Human-Machine Interface (HMI), Field Instruments, Control Valves, and Others), Type (Programmable Automation, Fixed or Hard Automation, Integrated Automation, and Flexible or Soft Automation), End User (Process Industries and Discrete Industries), Solution (Programmable Logic Controller (PLC), Distributed Control System (DCS), Supervisory Control and Data Acquisition (SCADA), Enterprise Level Controls, Programmable Automation Control (PAC), Plant Asset Management (PAM), Digitalization, Functional Safety, Emission Control), Mode of Automation (Semi-Automation and Fully-Automation), Systems (PID, Model Based Control, and Others), Regional Analysis and Forecast 2032.

Global Industrial Automation market size was USD 215.62 billion in 2023 and the market is projected to touch USD 498.26 billion by 2032, at a CAGR of 9.75% during the forecast period.

Industrial Automations includes the integration of control systems, robots, and computers to streamline manufacturing, assembly, and other tasks in various industries such as automotive, electronics, and food processing. In recent years, the market has experienced significant growth due to the increasing demand for higher productivity, quality, and safety in industrial operations.

Key drivers of this growth include advancements in technology, such as the Internet of Things (IoT) and Artificial Intelligence (AI), which enable greater connectivity and intelligence in automation systems. Additionally, factors such as rising labor costs, stringent regulations, and the need for faster production cycles have further fuelled the adoption of industrial automation solutions.

As a result, the market is expected to continue expanding, with opportunities emerging in emerging economies where industries are modernizing their operations to stay competitive in the global market landscape. However, challenges such as cybersecurity risks, integration complexities, and concerns about job displacement may pose hurdles to the widespread adoption of industrial automation.

Global Industrial Automation report scope and segmentation.

|

Report Attribute |

Details |

|

Estimated Market Value (2023) |

USD 215.62 billion |

|

Projected Market Value (2032) |

USD 498.26 billion |

|

Base Year |

2023 |

|

Forecast Years |

2024 – 2032 |

|

Scope of the Report |

Historical and Forecast Trends, Industry Drivers and Constraints, Historical and Forecast Market Analysis by Segment- Based on By Components, By Type, By End User, By Solution, By Mode of Automation, By Systems, & Region. |

|

Segments Covered |

By Components, By Type, By End User, By Solution, By Mode of Automation, By Systems, & By Region. |

|

Forecast Units |

Value (USD Million or Billion), and Volume (Units) |

|

Quantitative Units |

Revenue in USD million/billion and CAGR from 2024 to 2032. |

|

Regions Covered |

North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. |

|

Countries Covered |

U.S., Canada, Mexico, U.K., Germany, France, Italy, Spain, China, India, Japan, South Korea, Brazil, Argentina, GCC Countries, and South Africa, among others. |

|

Report Coverage |

Market growth drivers, restraints, opportunities, Porter’s five forces analysis, PEST analysis, value chain analysis, regulatory landscape, market attractiveness analysis by segments and region, company market share analysis. |

|

Delivery Format |

Delivered as an attached PDF and Excel through email, according to the purchase option. |

Global Industrial Automation dynamics

Key drivers include the increasing demand for higher productivity, operational efficiency, and cost reduction across industries. Industrial automation solutions offer the potential to streamline processes, minimize errors, and enhance output, thereby addressing these needs. Moreover, advancements in technology, such as the Internet of Things (IoT), Artificial Intelligence (AI), and machine learning, are driving innovation in automation systems, enabling greater connectivity, intelligence, and autonomy. This is leading to the development of more sophisticated and adaptable automation solutions capable of meeting the complex requirements of modern industrial operations.

Furthermore, rising labor costs, a scarcity of experienced workers, and the requirement for strict quality control and regulatory compliance are driving the development of automation solutions. Industries are increasingly looking to automation to address these difficulties while remaining competitive in the global marketplace. Furthermore, the COVID-19 pandemic has pushed the deployment of automation as firms seek to avoid disruptions and maintain operational continuity in the face of lockdowns and social distancing measures. However, constraints such as cybersecurity threats, interoperability issues, and a reluctance to invest in new technologies may impede market expansion.

Global Industrial Automation drivers

One of the primary drivers of the industrial automation market is the escalating demand for operational efficiency across industries. Companies are constantly striving to improve productivity, reduce costs, and enhance the quality of their products and services. Industrial automation solutions offer the means to achieve these objectives by streamlining processes, minimizing human error, and optimizing resource utilization.

For instance, automation can enable predictive maintenance, where equipment failures are anticipated before they occur, minimizing downtime and maximizing asset utilization. Additionally, automation facilitates real-time monitoring and control of manufacturing processes, allowing for immediate adjustments to optimize efficiency and output.

Rapid technological advances, especially in the Internet of Things (IoT), Artificial Intelligence (AI), and robotics, are driving innovation in industrial automation. These technologies improve connectedness, intelligence, and autonomy in automation systems, allowing for the development of more sophisticated and adaptive solutions. AI-powered algorithms, for example, may analyze massive quantities of data to detect trends and optimize manufacturing processes, whilst collaborative robots (cobots) can work alongside humans to improve productivity and flexibility on the factory floor. Furthermore, the introduction of cloud computing and edge computing allows for easy integration and data interchange between distant systems, improving the possibilities of industrial automation solutions.

Restraints:

Despite the numerous benefits of industrial automation, cybersecurity remains a significant concern for organizations. With increasing connectivity and digitization, industrial systems are becoming more vulnerable to cyber threats such as hacking, malware, and data breaches. A successful cyber-attack on automated systems can result in costly disruptions to operations, loss of sensitive data, and even physical damage to equipment or facilities. Consequently, companies are hesitant to fully embrace automation without robust cybersecurity measures in place, which may slow down the adoption of automation technologies.

Another restraint facing the industrial automation market is the complexity of integrating automation solutions with existing infrastructure and processes. Many industrial facilities operate legacy systems that may not be easily compatible with modern automation technologies. Additionally, each component of an automation system may be sourced from different vendors, leading to interoperability challenges. Ensuring seamless integration between disparate systems requires careful planning, customization, and sometimes significant investments in middleware or integration platforms. Moreover, ongoing maintenance and upgrades of automation systems can further complicate integration efforts, potentially delaying the adoption of automation solutions.

Opportunities:

The Industry 4.0 paradigm, which involves the integration of digital technology into industrial processes, represents a substantial opportunity for the industrial automation business. Industry 4.0 efforts use a variety of technologies, including IoT, AI, big data analytics, and cloud computing, to create smart, linked factories and supply networks. Companies that use these technologies can improve their operational visibility, agility, and efficiency.

For example, predictive maintenance powered by IoT sensors and AI algorithms allows for proactive equipment monitoring and maintenance, decreasing downtime and optimizing asset utilization. Similarly, digital twins, which are virtual representations of physical assets or processes, facilitate simulation, optimization, and predictive modelling, allowing organizations to test and develop production methods prior to deployment.

Segment Overview

This segment encompasses various components crucial for industrial automation systems. These components include sensors for data acquisition, industrial robots for automation tasks, industrial PCs for computing and control, machine vision systems for inspection and quality control, industrial 3D printing for additive manufacturing, human-machine interfaces (HMIs) for operator interaction, field instruments for measurement and control, control valves for fluid control, and other miscellaneous components contributing to the overall automation infrastructure.

The types of automation delineate different approaches to implementing automation in industrial processes. These include programmable automation, where tasks are controlled by a pre-programmed sequence; fixed or hard automation, characterized by dedicated machinery for specific tasks; integrated automation, which integrates disparate systems for seamless operation; and flexible or soft automation, allowing for adaptability and reconfiguration of processes to accommodate changing requirements.

The end-user segmentation categorizes industries based on the nature of their manufacturing processes. Process industries involve continuous or batch production of goods such as chemicals, oil, and gas, while discrete industries produce distinct items like automobiles, electronics, and consumer goods.

This segment encompasses various solutions tailored to specific automation needs. These solutions include programmable logic controllers (PLCs) for control logic, distributed control systems (DCS) for centralized control of complex processes, supervisory control and data acquisition (SCADA) systems for real-time monitoring and control, enterprise-level controls for overarching management, programmable automation controllers (PACs) for flexible automation, plant asset management (PAM) systems for maintenance optimization, digitalization tools for data-driven decision-making, functional safety systems for risk mitigation, and emission control solutions for environmental compliance.

This categorization distinguishes between semi-automation, where some tasks are automated but require human intervention, and fully automation, where processes are entirely autonomous without human intervention.

This segment encompasses different control systems employed in industrial automation. These include proportional-integral-derivative (PID) control systems for continuous processes, model-based control systems utilizing mathematical models for predictive control, and other specialized control systems tailored to specific industrial applications

Global Industrial Automation Overview by Region

North America, with its mature industrial infrastructure and technological prowess, remains a prominent market for industrial automation solutions. The region benefits from the presence of key industry players, robust R&D activities, and favourable government initiatives promoting digitalization and Industry 4.0 adoption. Similarly, Europe exhibits strong demand for automation technologies driven by stringent regulatory standards, a focus on sustainability, and a need for operational excellence.

Asia-Pacific emerges as a lucrative market fuelled by rapid industrialization, urbanization, and the proliferation of manufacturing activities in countries like China, India, and Japan. These nations are investing heavily in automation to enhance productivity, efficiency, and competitiveness in the global market. Additionally, the adoption of automation is accelerating in emerging economies across Latin America, the Middle East, and Africa, propelled by growing investments in infrastructure, rising labor costs, and a burgeoning manufacturing sector. However, regional disparities exist, with some regions facing challenges such as inadequate infrastructure, limited access to technology, and geopolitical uncertainties, which may impede market growth.

Global Industrial Automation market competitive landscape

Major companies such as Siemens AG, ABB Ltd., Schneider Electric SE, Rockwell Automation Inc., and Mitsubishi Electric Corporation dominate the market with their comprehensive portfolios of automation solutions and extensive global presence. These industry leaders focus on strategic initiatives such as mergers and acquisitions, partnerships, and product launches to strengthen their market position and expand their customer base. Additionally, there is a proliferation of smaller players and startups specializing in niche automation technologies, driving innovation and addressing specific industry needs.

Furthermore, the market is witnessing increasing collaboration between automation providers and technology companies to integrate emerging technologies such as artificial intelligence, machine learning, and the Internet of Things into automation systems, enabling smarter, more efficient industrial processes. As competition intensifies, companies are also investing in research and development to develop next-generation automation solutions capable of addressing evolving customer requirements, such as flexibility, scalability, and interoperability.

Key Players:

Global Industrial Automation Recent Developments

Scope of global Industrial Automation report

Global Industrial Automation report segmentation

|

ATTRIBUTE |

DETAILS |

|

By Components |

|

|

By Type |

|

|

By End User |

|

|

By Solution |

|

|

By Mode of Automation |

|

|

By Systems |

|

|

By Geography |

|

|

Customization Scope |

|

|

Pricing |

|

Objectives of the Study

The objectives of the study are summarized in 5 stages. They are as mentioned below:

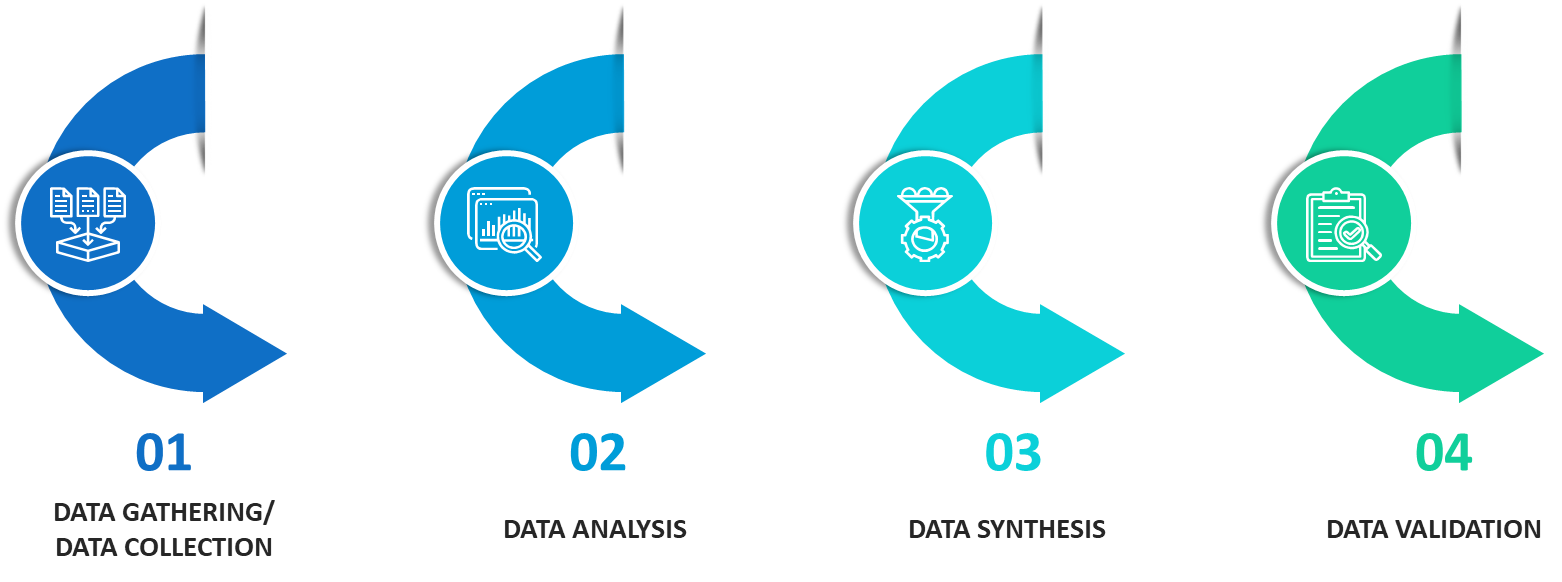

Research Methodology

Our research methodology has always been the key differentiating reason which sets us apart in comparison from the competing organizations in the industry. Our organization believes in consistency along with quality and establishing a new level with every new report we generate; our methods are acclaimed and the data/information inside the report is coveted. Our research methodology involves a combination of primary and secondary research methods. Data procurement is one of the most extensive stages in our research process. Our organization helps in assisting the clients to find the opportunities by examining the market across the globe coupled with providing economic statistics for each and every region. The reports generated and published are based on primary & secondary research. In secondary research, we gather data for global Market through white papers, case studies, blogs, reference customers, news, articles, press releases, white papers, and research studies. We also have our paid data applications which includes hoovers, Bloomberg business week, Avention, and others.

Data Collection

Data collection is the process of gathering, measuring, and analyzing accurate and relevant data from a variety of sources to analyze market and forecast trends. Raw market data is obtained on a broad front. Data is continuously extracted and filtered to ensure only validated and authenticated sources are considered. Data is mined from a varied host of sources including secondary and primary sources.

Primary Research

After the secondary research process, we initiate the primary research phase in which we interact with companies operating within the market space. We interact with related industries to understand the factors that can drive or hamper a market. Exhaustive primary interviews are conducted. Various sources from both the supply and demand sides are interviewed to obtain qualitative and quantitative information for a report which includes suppliers, product providers, domain experts, CEOs, vice presidents, marketing & sales directors, Type & innovation directors, and related key executives from various key companies to ensure a holistic and unbiased picture of the market.

Secondary Research

A secondary research process is conducted to identify and collect information useful for the extensive, technical, market-oriented, and comprehensive study of the market. Secondary sources include published market studies, competitive information, white papers, analyst reports, government agencies, industry and trade associations, media sources, chambers of commerce, newsletters, trade publications, magazines, Bloomberg BusinessWeek, Factiva, D&B, annual reports, company house documents, investor presentations, articles, journals, blogs, and SEC filings of companies, newspapers, and so on. We have assigned weights to these parameters and quantified their market impacts using the weighted average analysis to derive the expected market growth rate.

Top-Down Approach & Bottom-Up Approach

In the top – down approach, the Global Batteries for Solar Energy Storage Market was further divided into various segments on the basis of the percentage share of each segment. This approach helped in arriving at the market size of each segment globally. The segments market size was further broken down in the regional market size of each segment and sub-segments. The sub-segments were further broken down to country level market. The market size arrived using this approach was then crosschecked with the market size arrived by using bottom-up approach.

In the bottom-up approach, we arrived at the country market size by identifying the revenues and market shares of the key market players. The country market sizes then were added up to arrive at regional market size of the decorated apparel, which eventually added up to arrive at global market size.

This is one of the most reliable methods as the information is directly obtained from the key players in the market and is based on the primary interviews from the key opinion leaders associated with the firms considered in the research. Furthermore, the data obtained from the company sources and the primary respondents was validated through secondary sources including government publications and Bloomberg.

Market Analysis & size Estimation

Post the data mining stage, we gather our findings and analyze them, filtering out relevant insights. These are evaluated across research teams and industry experts. All this data is collected and evaluated by our analysts. The key players in the industry or markets are identified through extensive primary and secondary research. All percentage share splits, and breakdowns have been determined using secondary sources and verified through primary sources. The market size, in terms of value and volume, is determined through primary and secondary research processes, and forecasting models including the time series model, econometric model, judgmental forecasting model, the Delphi method, among Flywheel Energy Storage. Gathered information for market analysis, competitive landscape, growth trends, product development, and pricing trends is fed into the model and analyzed simultaneously.

Quality Checking & Final Review

The analysis done by the research team is further reviewed to check for the accuracy of the data provided to ensure the clients’ requirements. This approach provides essential checks and balances which facilitate the production of quality data. This Type of revision was done in two phases for the authenticity of the data and negligible errors in the report. After quality checking, the report is reviewed to look after the presentation, Type and to recheck if all the requirements of the clients were addressed.